About us

We are committed to establishing long-term and stable cooperative relations with our global partners

Possess

+

R & D personnel

Possess

+

production line

Cover an area of

+

square meters

Possess

+

R & D personnel

Possess

+

production line

Cover an area of

+

square meters

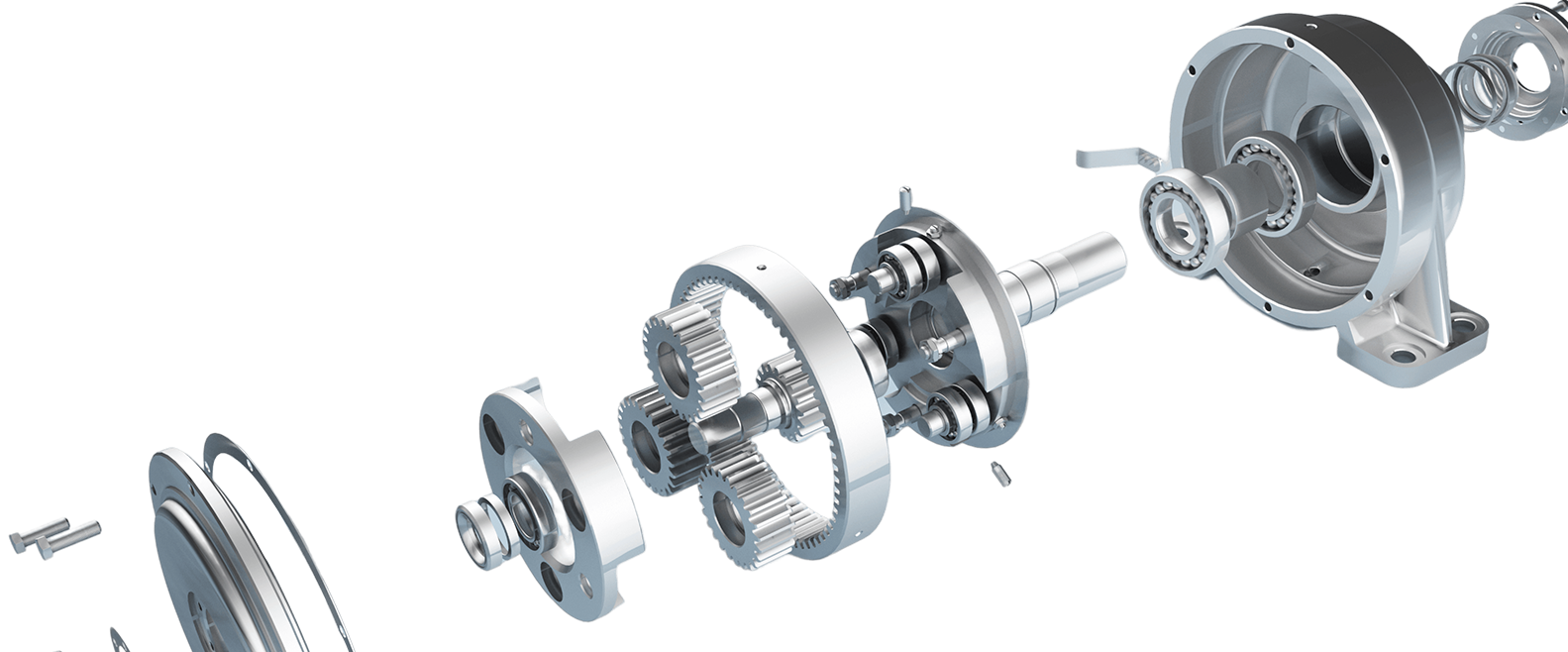

Committed to developing and promoting more environmentally friendly and efficient bearing products and technologies

•••

Your local BOWER dealer can provide you with technical support and sales assistance.

More50+

Countries and regions

$90Million

annual output value

Instructions on bearing solutions, if more specific problems or require deeper solutions,

It is recommended to directlyContact usfor consultation.

From product research and development to pre-sale, sale and after-sales service, every link truly takes customer demand as the center,

adhere to the user first, quality service, continuous excellence route.

Do whatever you want, satisfy everything

Across the country, worry-free service

Transportation is controllable and the product is not damaged

Extra long warranty, no worries about quality

Efficient, convenient and smooth

Facing the challenge of global climate change, reducing carbon emissions in industrial production has become a common goal for many companies. BOWER is responding to this challenge by optimizing its production processes, including reducing energy consumpt

MoreWith the rapid development of industrial automation technology, the demand for high-performance bearings is growing day by day. BOWER has recently made significant technological progress in the field of industrial automation, especially in providing high-

MoreAs the field of offshore engineering continues to develop, especially in offshore wind power and oil and gas exploration, BOWER's bearing products have demonstrated their strength in meeting technical challenges in extreme marine environments. Technology

MoreBOWER recently announced that its technical cooperation with several world-renowned automobile manufacturers has made new progress. The collaboration focuses on jointly developing high-efficiency bearing technologies to support new challenges facing the a

More