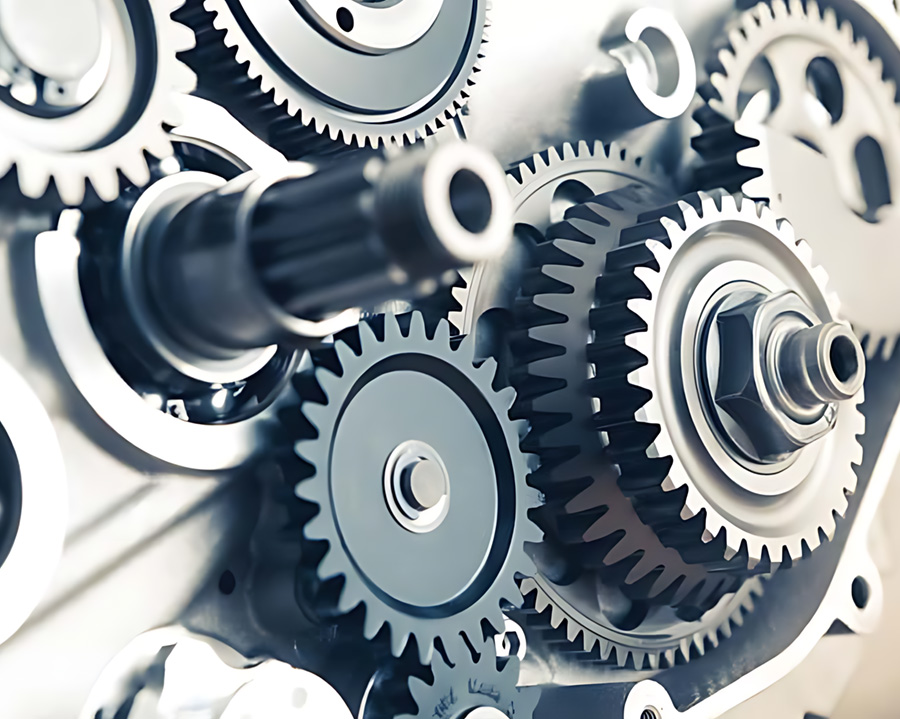

Gear units and transmission systems operate in almost every industrial process and are available in every possible shape and size, so they face a wide range of operating requirements and conditions. But regardless of the industry or application, all industrial drives face a common challenge: they must operate as reliably, efficiently and cost-effectively as possible. Industrial gearbox solutions meet these requirements and can help manufacturers and users find ways to optimize transmission performance and reliability. By using a systems approach, we can help you unlock the full potential of your gear units and improve performance and reliability in several ways:

large torque

Reduced size design

long lasting

Gain operational reliability

Improve energy efficiency

The places where mining machinery and engineering machinery are active are mostly mining sites in mountainous areas and desert areas that are far away from ordinary human life. Sometimes they even work 2,000 meters underground. There are many types of suc

More

Motor bearings, also known as motor bearings or motor bearings, are special bearings specially used on electric motors or motors. The bearing used in the motor is a part that supports the shaft. It can guide the rotation of the shaft and can also bear the

More

Wind power generation main bearing belongs to the field of wind power generators. The characteristics are: main bearing upper outer ring, main bearing lower outer ring, thrust cylindrical rollers, cage, main bearing inner ring. There are two rows of thrus

More

There are many types of aircraft bearings. In response to customer demands for reduced weight, reduced environmental pollution and high performance from bearings, bearing systems have become more complex and require greater reliability and quality control

More