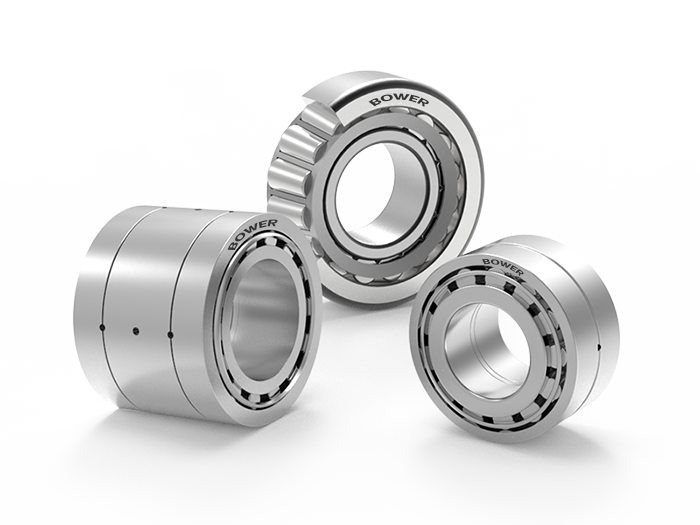

Introduction Maintenance and care of bearings is essential to ensure their optimal performance and extended service life. Even the highest quality BOWER bearings require proper maintenance to prevent early failure. This article will explore how to properl

More

Define the difference

A rolling bearing refers to a bearing whose rolling elements perform rolling motion on a raceway; while a sliding bearing refers to a bearing that operates under the action of sliding friction.

Differences in bearing categories

BOWER

More

To assist you in selecting the appropriate bearing type, BOWER provides the following guide.

1. Bearing radial load

The bearings that mainly bear radial loads are radial bearings. The nominal contact angle a0 of this type of bearing is <=45°. Rolle

More

In the operation of mechanical equipment, the care and maintenance of bearings is crucial. For BOWER bearings, maintenance work mainly focuses on three key aspects. Today, we'll find out.

Ensure BOWER bearings are lubricated and clean: Before inspecting B

More

In the rapidly developing power industry, bearings, as key components, play an important role in many motors. Especially during motor maintenance, the insulation treatment of bearings requires special attention. BOWER has extensive experience in this area

More

During grinding operations, intense heat is often generated at the contact area between the workpiece and the grinding wheel, which leads to a sudden increase in temperature in this area. According to theoretical analysis and actual measurement of heat co

More